Joker Industrial Co., Ltd.

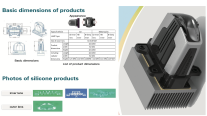

LED Lamp miniature module with silicone lens

Explore product

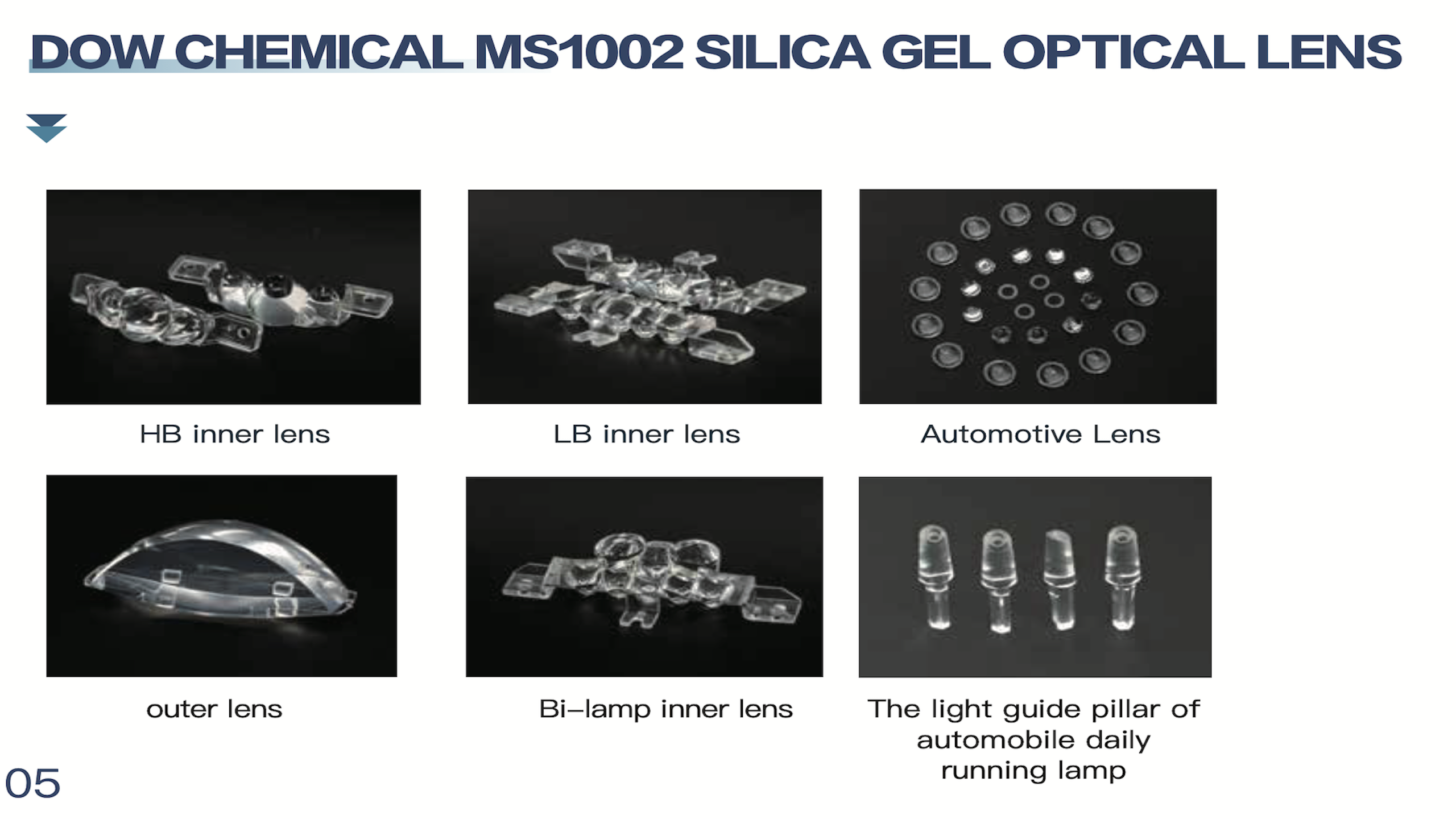

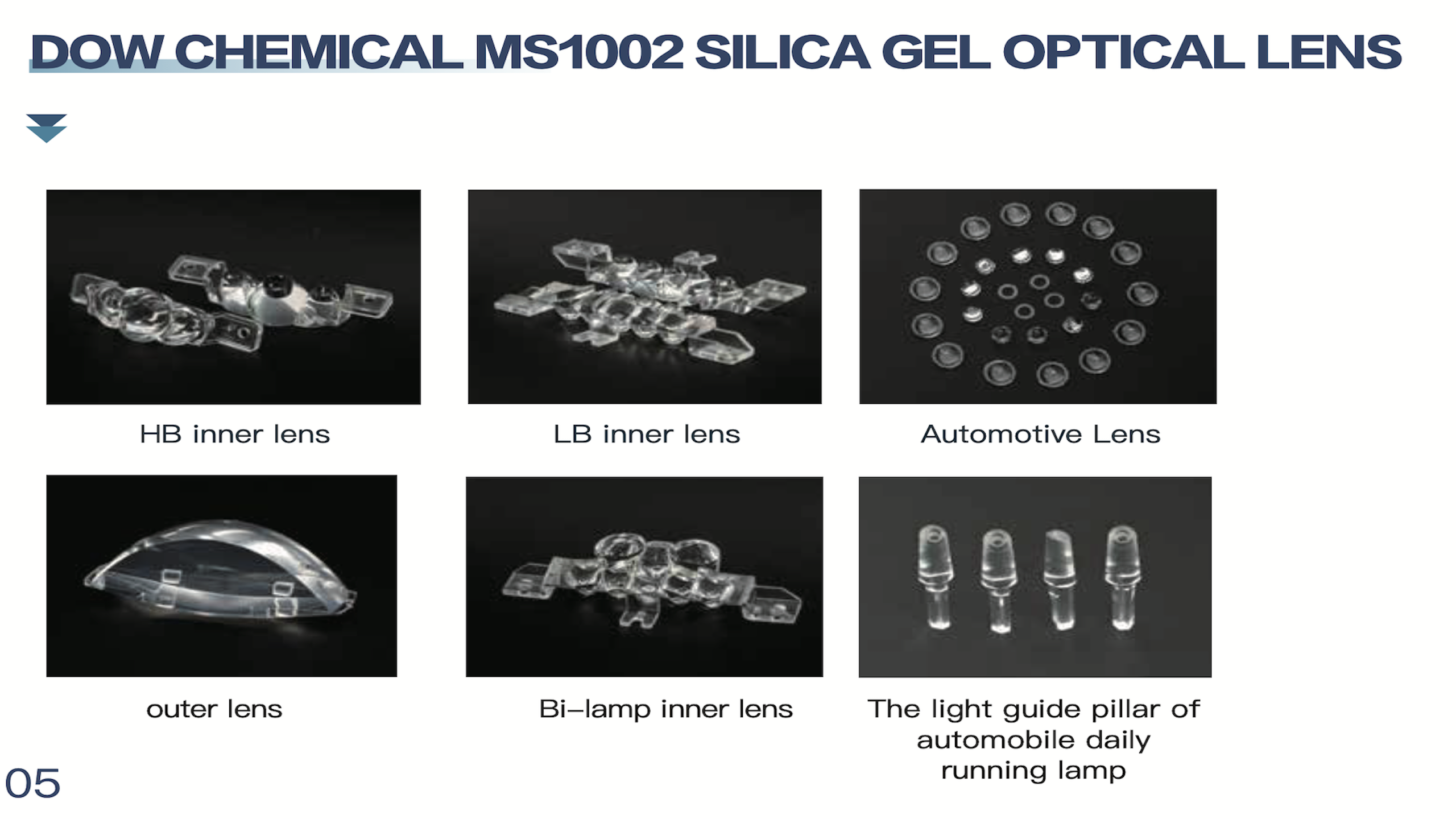

LSR Silicone optical lens

Explore product

LED Lamp miniature module with silicone lens

Explore product

LSR Silicone optical lens

Explore product

LED Lamp miniature module with silicone lens

Explore product

LSR Silicone optical lens

Explore productAddress

Joker Industrial Co., Ltd.

10 Zhangbin E. 7th, Hsien Hsi Hsiang, Changhua County

Taiwan 50741

Taiwan

Telephone+886 4 758 0187

Fax+886 4 758 1747

Discover more from us

Follow us on

About us

LSR (liquid silicone rubber) have lots of advantages compare with traditional PC/PMMA and glass.

JOKER Industrial is making a great improvement on molding technology and step into all kinds of LSR industrial such as, silicone sealant O-ring for high-end sanitary industry, optical lens for automotive head lamp, optical lens for electric-motorbike headlamp, and now we’re developing into lens for laser applications.

With LSR manufacturing technology, our silicone lens stand out from other materials with: Non-yellowing, 94% plus of light transmittance, high forming flexibility, high temperature resistance from Celsius -40 to +240, green and nontoxic…plenty features for optic/lens application.

JOKER has two production sites located in Changhua, Taiwan with 30,000m2 and Anhui, China with 1,300m2. With 8 sets of Wittmann Battenfeld LSR injection machines, 300,000 level dust-free workshop, constant temperature and humidity PCB board electronic warehouse, quality assurance laboratory, and light distribution room Electrical performance room, clean silicon plastic injection work- shop, and mold processing workshop. Equipped with automotive lighting fixture light distribution performance testing machine, precision intelligent light detector, light color distribution performance measurement machine, LED module light color electrical testing machine, LED lights and lighting fixture accelerated aging life testing machine, automotive electronic immunity testing machine, power failure simulator, 8 Austrian ELMET glue supply machines, RD design open cold runner silicone mold technology team of silicone injection machine, PhD in optical design, and PhD in electrical control design.

LSR LIQUID SILICONE

Injection molding liquid silica gel (LSR) is a new kind of organic silica gel material, which is non-toxic, tasteless, weatherproof and chemically inert. This kind of silica gel has low viscosity (it has certain fluidity and irreformability before vulcanization) , uses Elmet rubber feeding machine to mix AB agent, Wittmann Battenfeld silicone gel machine to mix two groups of AB agent and inject mould, then rapid vulcanization, injection molding products.

High and low temperature resistance (use temperature from -40 ° C, +240° C, cold and heat cycle test, the product is not yellowing)

Good weather resistance (UV resistance)

High light transmittance

High degree of automatic molding

Good waterproof Good electrical characteristics

Elastic, malleable Safety recognition (FDA, NSF,Mil,UL)

There are no by-products The product has a long service life during vulcanization

Why use optical grade silicone

Today, the development of cutting-edge high-power LED technology is facing new challenges. The new generation of LEDs will need to maintain their optimum luminescence and lumen values over time and be able to be used in micro-structural design at compact sizes; however, these requirements present a major challenge to the current optical plastic components. On the contrary, optical silica is the material that can provide optical transparency, durability, and design hyperboloid and free- form surfaces.

The advantageous properties of silicone gel materials

High light transmission Can meet the design requirements of transparency, atomization, and astigmatism, with excellent results.

Luminous flux loss In the hot and humid environment, can maintain a variety of lens projection accuracy.

Durability UV resistance and crack resistance is very good; high temperature stability, showing that it can maintain a good long-term luminescence, and will not cause problems such as heat-resistant plastic yellowing.

Our product groups

Downloads

Documents

Keywords

- LSR liquid silicone rubber optical lens

- LSR Flüssigsilikonkautschuk-Optiklinse

- LSR liquid silicone rubber laser lens

- LSR Flüssigsilikonkautschuk-Laserlinse

Our Products

LSR liquid silicone rubber optical laser lens

JOKER industrial could produce OEM/ODM LSR(liquid silicone rubbe) optical lens throguh software such as Lucid shape perfectly. Shorten the R&D developement time period.

Owing to its thermo setting characteristic, LSR lens have several features as below:

- Excellent impact resistance: temperature from -40 ° C to + 230 ° C, cold and hot cycle, the product is not yellowing

- Strong weather resistance (UV resistance)

- Excellent waterproof performance

- Good electrical characteristics

- High light transmittance, elasticity, high ductility

- Safety certification (FDA, NSF, Mil, UL)

- High degree of automatic molding

- There are no by-products during vulcanization

- Long service life of anti-aging products

- Optical transparency (optical transmittance 94%) , durability, and materials of hyperboloid and free-form surfaces for optical design

- High light transmittance: Can Meet the design requirements of transparency, atomization, and astigmatism, the effect is excellent.

- Maintenance of light flux: in hot and humid environment, can maintain the material properties, and the various lens transmittance can be maintained for a long time.

- Durability:-- UV resistance, high temperature resistance and crack resistance is very good... Thoroughly solve the yellowing problem of plastics.

LSR silicone sealant O-ring

IDEAL USES:

• MEDICAL DEVICE• HOUSEHOLD• ELECTROTECHNICS• FOOD DEVICE• AUTOMOTIVE• ECOLOGY• MEDICAL• TELEPHONY

Liquid Silicone Rubber LSR

LSR is a two-components liquid silicone rubber used to produce elastic items with the injection moulding method.

For example its molecular structure is characterized by bonds where the carbon is substituted with silicon; it follows that both the technology for its transformation and the kinds of its uses are peculiar..

The products in LSR are created by the chemical reaction of two different gelatinous components.

The cross-link process, similar to the vulcanisation one, can be speed up or down by the temperature, but it’s always irreversible as soon as the two components come into contact each other.

Therefore the LSR cannot be recovered and cannot be moulted with the same technology used for pastes and mixtures able to be vulcanized.

This material is then transformed using specific injection machines which let to obtain the best results.

LSR Characteristics

The products vulcanized with the Liquid Silicone Rubber have the following characteristics:

• Excellent high temperature resistance +250° C

• Excellent low temperature resistance and flexibility – 60°C

• Very good thermal stability

• Excellent resistance to ageing and great stability to ozone and UV rays

• Very good dielectric behaviour in a wide temperature range

• Very good stretch characteristics inside the provided hardness range

• Very good stretch against breaking

• Very good ultimate tensile stress

• Physiological independence

• Inertless (no taste or smell)

• Very good size stability

• The products satisfy the BGA, FDA, KTW rules regarding the contact with food.

SPECIALIZED ITEMS:

Applications for oil resistance

Electrical conductivity

Fuel resistance

Medical contact

Fluorurate silicone

Colours

Generally the Liquid Silicone Rubber are transparent; they can be coloured adding a third component, a couloring paste, into the mixer.

Now it’s possible to produce details in the following colours: RED, WHITE, BLACK, GREY, GREEN, SKY-BLUE, YELLOW; other colours can be custom made for special items.

Hardness

Hardness = range 20 – 80 Shore A

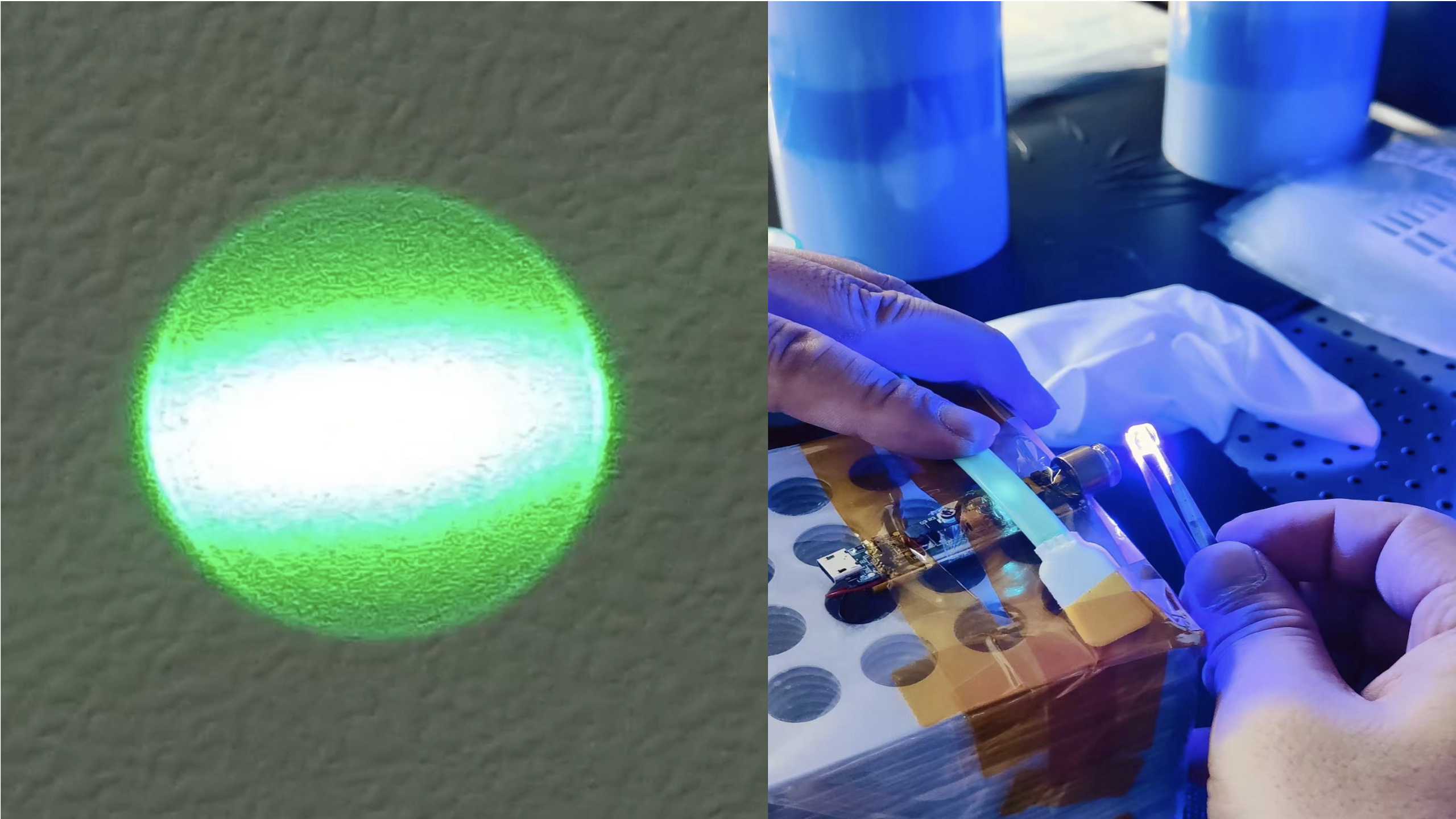

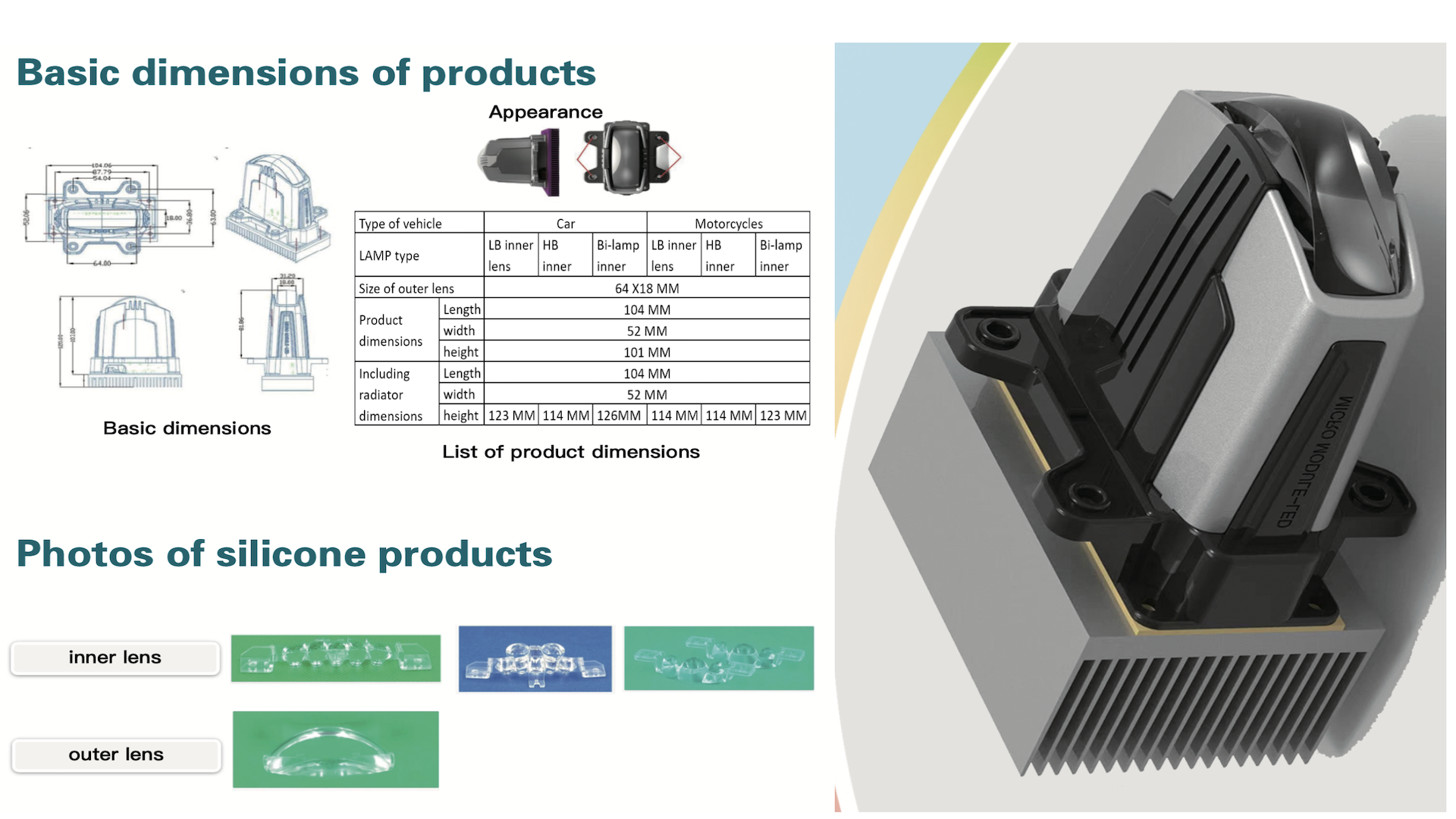

LED Lamp miniature module with silicone lens

The new generation of high-power LED, the appearance of thin and compact shape, coupled with complex microstructure of optical design. According to the development trend, it is a big challenge to the present optical elements, which need the materials with high heat resistance and long-term maintenance of the best luminescence and lumen value.

Optical silica gel can provide optical transparency (optical transmittance 94%) , durability, and materials of hyperboloid and free-form surfaces for optical design

High light transmittance: Can Meet the design requirements of transparency, atomization, and astigmatism, the effect is excellent.

Maintenance of light flux: in hot and humid environment, can maintain the material properties, and the various lens transmittance can be maintained for a long time.

Durability:-- UV resistance, high temperature resistance and crack resistance is very good... Thoroughly solve the yellowing problem of plastics.

***LSR liquid silicone lens***

- Excellent impact resistance: temperature from -40 ° C to + 230 ° C, cold and hot cycle, the product is not yellowing

- Strong weather resistance (UV resistance)

- Excellent waterproof performance

- Good electrical characteristics

- High light transmittance, elasticity, high ductility

- Safety certification (FDA, NSF, Mil, UL)

- High degree of automatic molding

- There are no by-products during vulcanization

- Long service life of anti-aging products

All kinds of LSR liquid silicone rubber OEM/ODM

Professional manufacturer of elastic parts made of two component liquid silicon rubber (LSR – Liquid Silicon Rubber).

Advantages of the LSR application

- Extensive range of applications from – 50 to + 250 °C

- High flashpoint and advantageous fire behavior

- Good electrical insulation property

- Excellent resistance to weathering and aging

- High dimensional stability even under long-term load (sealing)

- High bio-compatibility, odor and taste neutrality (medical use, baby care, etc.)

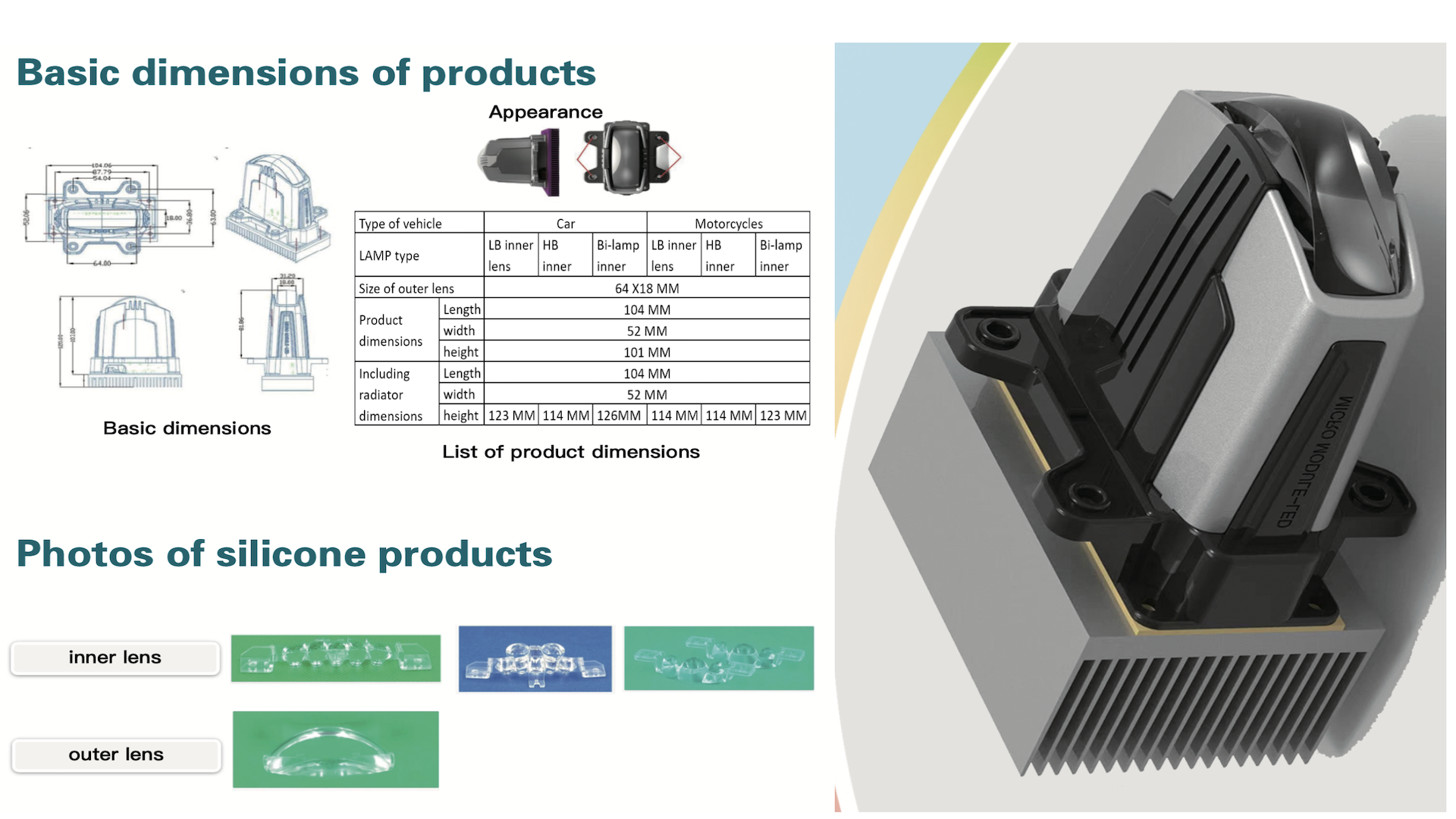

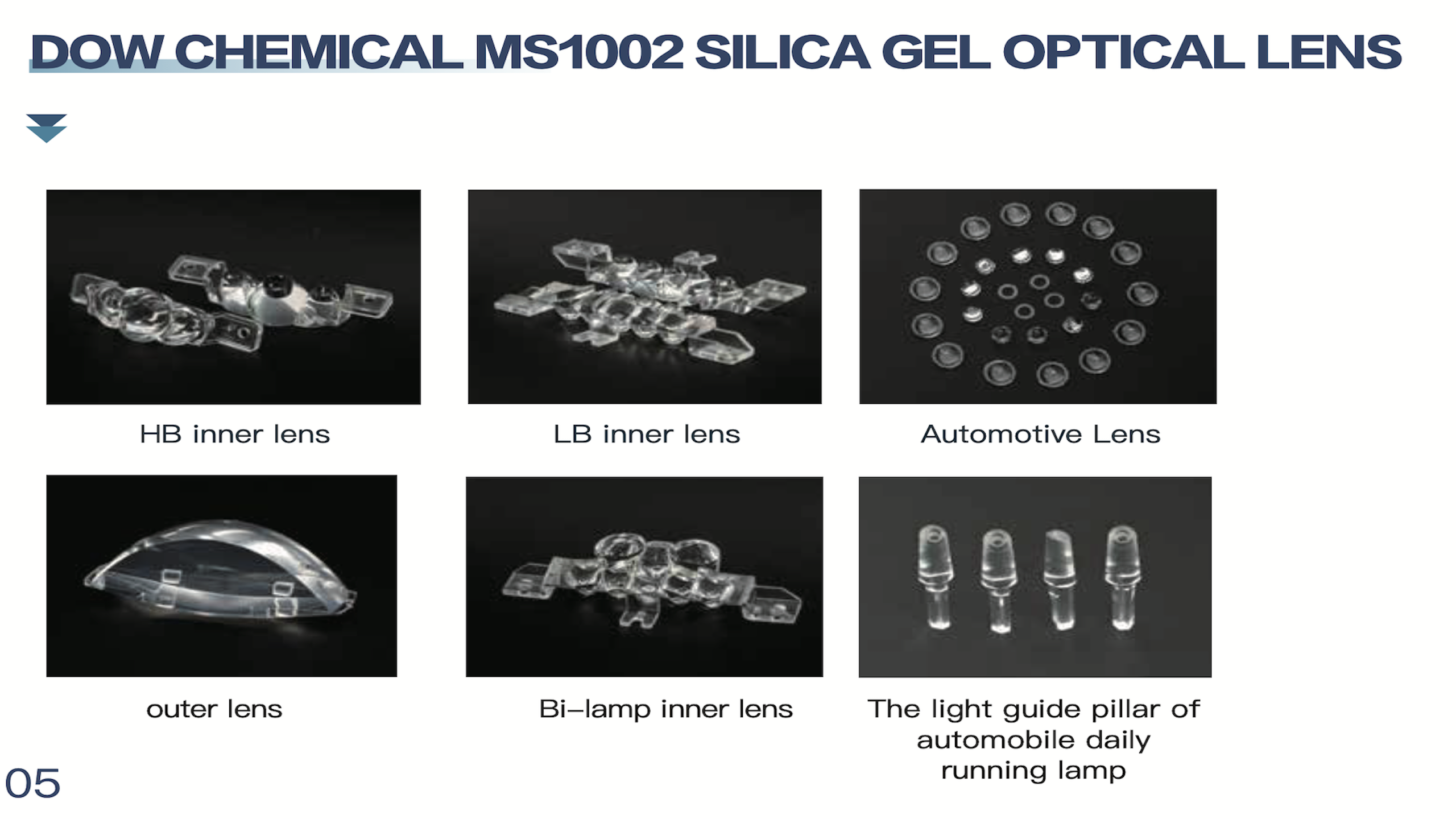

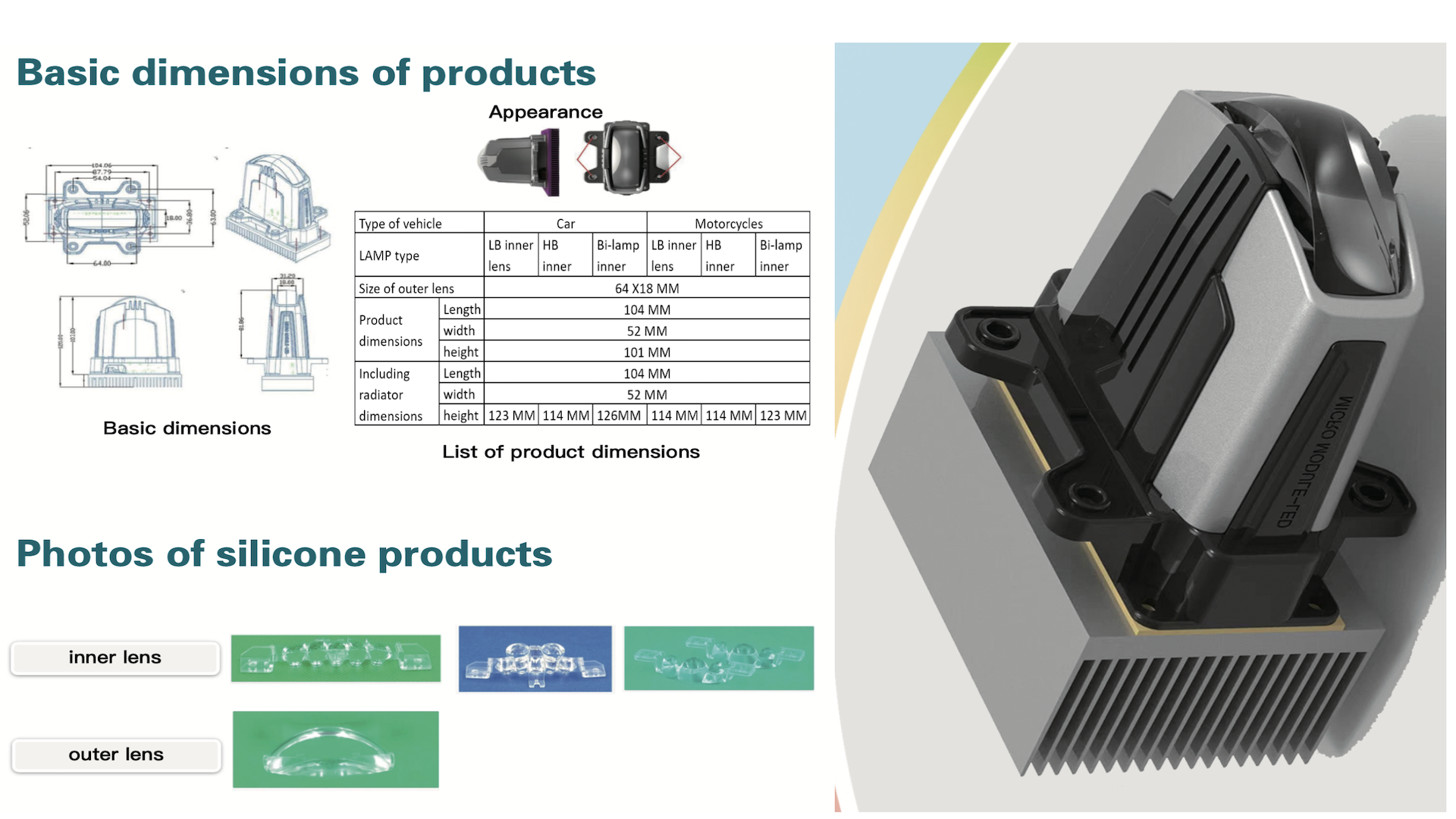

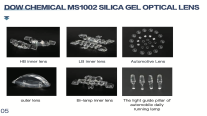

LSR Silicone optical lens

JOKER industrial could produce OEM/ODM LSR(liquid silicone rubbe) optical lens throguh software such as Lucid shape perfectly. Shorten the R&D developement time period.

Owing to its thermo setting characteristic, LSR lens have several features as below:

- Excellent impact resistance: temperature from -40 ° C to + 230 ° C, cold and hot cycle, the product is not yellowing

- Strong weather resistance (UV resistance)

- Excellent waterproof performance

- Good electrical characteristics

- High light transmittance, elasticity, high ductility

- Safety certification (FDA, NSF, Mil, UL)

- High degree of automatic molding

- There are no by-products during vulcanization

- Long service life of anti-aging products

- Optical transparency (optical transmittance 94%) , durability, and materials of hyperboloid and free-form surfaces for optical design

- High light transmittance: Can Meet the design requirements of transparency, atomization, and astigmatism, the effect is excellent.

- Maintenance of light flux: in hot and humid environment, can maintain the material properties, and the various lens transmittance can be maintained for a long time.

- Durability:-- UV resistance, high temperature resistance and crack resistance is very good... Thoroughly solve the yellowing problem of plastics.

Our Contact Persons

Ryan HUANG

General management

Board of Management