Wire laying machine

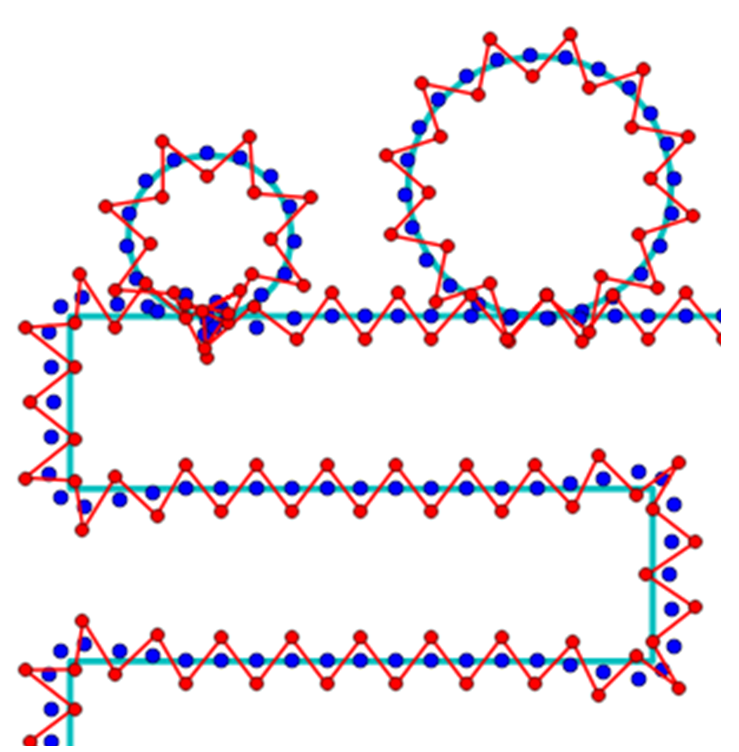

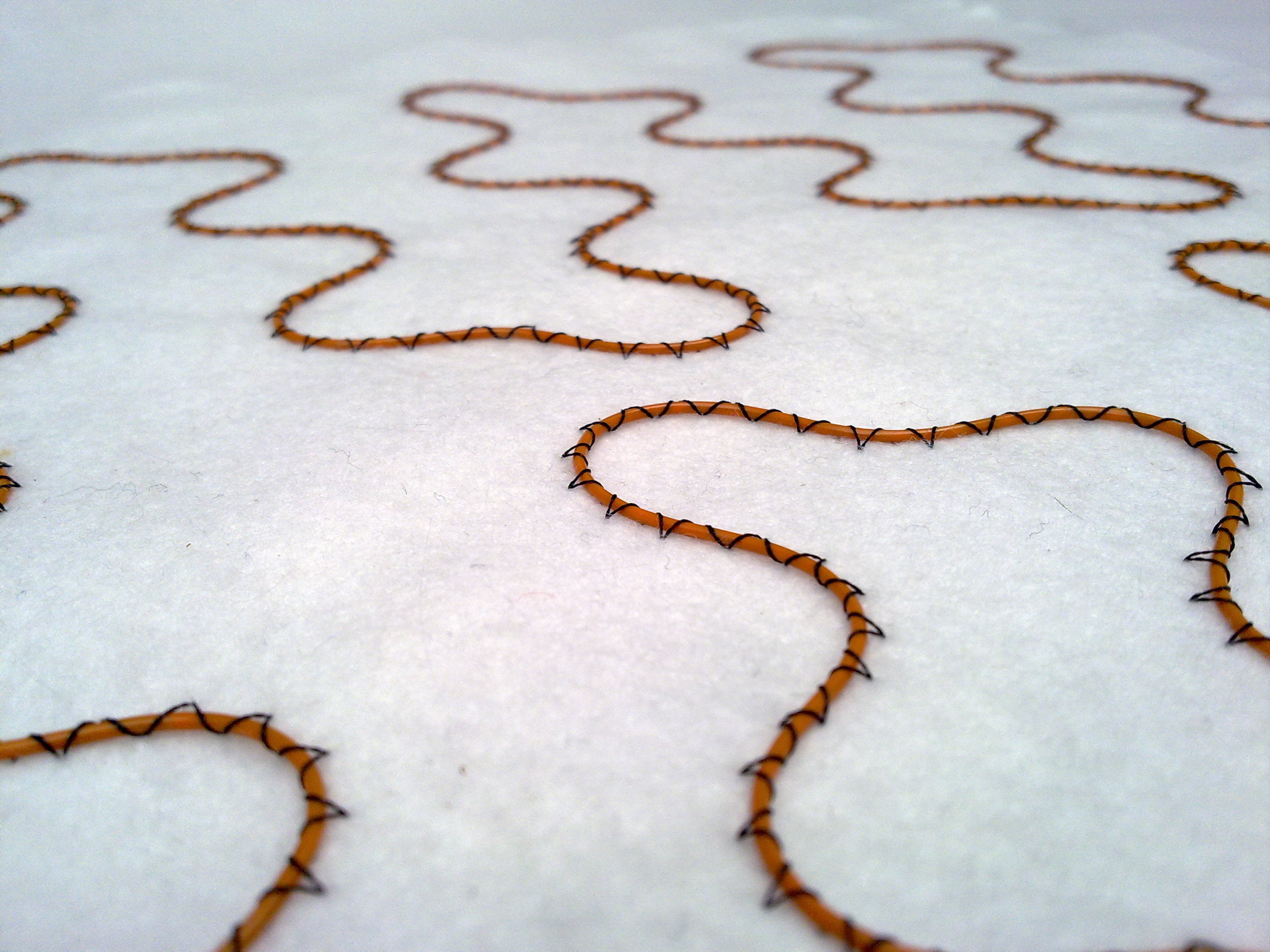

In the so-called wire laying of Filacon Systems, a component (such as a heating pad) is virtually created on the PC before the actual production process. The wire is placed in front of a sewing head and fixed with needle and thread. The wire (hose, fiber, cable) can have a different thickness, flexibility and surface to which the machine is adapted. The base material, e.g. a polyester fleece is moved NC controlled by a pantograph in the possible directions x and y. At speeds of 600 to 800 stitches per minute, up to 12 m of wire per hour can be laid exactly for each laying head, depending on the thickness of the wire. The advantage compared to conventional textile technologies such as weaving is that the wire can be arranged in any direction, at an angle between 0 and 359 degrees. Any laying pattern is possible.

The process is regarded as a central automation technology in order to quickly and cost-effectively cover different substrates with wires, tubes, or reinforcing fibers. Especially in the case of complex components, which have to be equipped with several different wires, the pair or triple head machines offer completely new possibilities to combine up to three different laying materials. A reinforcement can also be created by the application of fibers.

Filacon Systems has been involved in wire laying with its mother of Tajima GmbH for about 20 years. During this time numerous other areas of application for the technology were entered. Thus, most of the systems are found in seat heating manufacturers, which are supplied worldwide. However, Filacon customers also integrate sensoric components, such as medical components, or sports monitoring, using wire laying machines. Smart textiles and, above all, entertainment electronics play an important role in functional textiles.

In recent years, several research projects have been applied and have contributed to a significant increase in machine speed. In addition, large wire coils can now be processed with several kilometers of wire. In addition, the new networking facility provides the production manager with an optimal allocation of orders and monitoring of individual laying systems.