Anhui Shinhoo Canned Motor Pump Co., Ltd.

Adresse

Anhui Shinhoo Canned Motor Pump Co., Ltd.

Anhui Hefei

High-Tech Zone No. 780, Ming Chuan Road

230088

China

Telefon+86 551 6237 9807

Fax+86 551 6237 9807

Entdecken Sie mehr von uns

Über uns

(Shinhoo) As a wholly-owned subsidiary of Zhejiang Dayuan Pump Co., Ltd. (Shanghai Stock Exchange-stock code: 603757), Shinhoo is specialized in canned motor pump manufacturing. As required by different countries and areas, our related products obtain the certificate successfully such as CCC, GS, UL and CE, as well as passed required tests such as RoHS, REACH and EEI. All of these ensured the safety, stability, reliability, durability and legality of our products in the market. With abundant material resources, sound management system and high-tech talents, we have formed our own core competitiveness and space for sustainable development.

Our company wholeheartedly supports both OEM (Original Equipment Manufacturer) and ODM. We are customer-centric, committed to providing customers with the best products and services, and continuously improving the experience of end users to ensure that they receive reliable and efficient canned pump products that exceed expectations.

Unsere Produktgruppen

Unsere Anwendungsbereiche / Lösungen

Downloads

Dokumente

Keywords

- pump

- High-efficiency pumps

- Circulating pumps

- OEM

- Shinhoo

Unsere Produkte

PFM 03-30 EC PRO

PFM03-30EC Pro self priming permanent magnet centrifugal pump

TECHNICAL DATA

Max. flow(m³/h):5.5

Rated flow(m³/h):3

Design pressure:1.0MPa

Max. head(m):45

Rated head(m):30

Protection class:IP44

Voltage:AC 220V/50Hz

Max. input power:600W

Max. speed:5000rpm

APPLICATION FIELD

1. Pressurization of commercial water

2. Groundwater intake for domestic use

3. Pressurization of domestic water supply

FEATURES AND BENEFITS

Product certification

Products comply with CCC, GS (CE), EMC, RoHS, REACH, WRAS certification requirements.

Benefits

1. The permanent magnet synchronous motor control algorithm without position sensors effectively reduces motor vibration, decreases pump noise, and improves pump efficiency.

2. Intelligent control technology is employed, which detects motor armature current and provides feedback to control motor speed, enabling adaptive adjustment for varying operating conditions. This solution solves the issue of high energy consumption in conventional shielded pumps, resulting in highly efficient and low-noise operation.

DESCRIPTION

1 Product Conditions

1.1 Media requirements

Use medium:water

Medium water temperature:0℃~50℃

Medium PH value:6.5~8.5

Medium hardness: ≤25°dH

Solid impurity content in the medium:solid impurity diameter and length direction ≤ 0.1mm, and volume ratio ≤ 0.1%.

1.2 Use environment requirements

How to use:keep the axis horizontal

Altitude: <1000m

Operating environment temperature: 0℃~55℃ (no freezing phenomenon in the pipeline and water pump)

Use environment humidity ≤95%

1.3 Storage environment requirements

Storage ambient temperature: -20°C~60°C (no freezing in pipelines and pumps)

Storage environment humidity ≤95%

2. Product installation direction diagram

When the water pump is installed, the pump shaft must be in a horizontal position, and the pump shaft is allowed to be installed at an angle of ±5°.

The installation of the water pump in the system should ensure that the pump cavity is filled with liquid so that the water pump can operate normally.

Pipeline installation must be carried out according to the diagram, and the rubber pads should be well supported.

3. Start and stop of water pump

Start-up time: The start-up time of the water pump is less than 5s, that is, the time from power-on to maximum speed

Downtime: the pump stop time < 3s, that is, the time from when the pump is powered off to when it stops running

4. Motor type

Motor type: permanent magnet synchronous motor

Enameled wire material: copper

Magnetic steel material: NdFeB

DC cold state resistance of the motor at 20°C: 3.77±5%Ω

Insulation class: F

MEGA S 65-12F

Mega S 65-12F High Efficiency Erp Flange automotive booster Circulator Pump

TECHNICAL DATA

Enclosure class:IPX4D (EN 60529).

Insulation class:H.

Supply voltage:1 × 230 V ± 10 % 50 Hz, PE

Digital input:PWM 0–10 V

Analog input:4–20 mA. 0–10 W direct current

Connection bus input:Modbus RTU

Leakage current:Ileakage < 3.5 mА. Leakage current is measured in accordance with EN 60335-1.EMC

Standards applied: EN61000-3-2, EN61000-6-3, EN61800-3-3, EN55014-1 and EN55014-2

APPLICATION FIELD

MEGA S circulator pumps are highly effective both in new systems and as a replacement to the ones being in use. The pump is ideal for systems with an automatic pressure adjustment. These pump series allow avoiding the use of expensive bypass valves and similar components.

• Heating systems:

– main pump,

– secondary circuit lines,

– heating surfaces.

• Cooling and air conditioning systems;

• Ground source heat systems;

• Solar energy systems.

FEATURES AND BENEFITS

Characteristics:

1.The Mega automatic circulator pump provided with self-adaptive mode AUTO (Initial setting), No needs adjustment. It can be readily started and automatically to meet the actual needs of the system.

2.Has 0-10V and temperature control function. Realize the control of the motor speed, to meet the different flow requirements of the system.

3.The flange circulator pump comes with over-voltage and over-current protection to prevent the risk of burning during use.

4.The junction box is on the top of the motor, which adopts button-type gear adjustment, and the panel displays the current operating mode and flow.

5.The power interface and signal interface adopt lead wire or without wire, and the user can wire it by himself.

6.The machine base is provided with a condensate drain tank

Installation and Safety Instructions:

1. Liquid may be high temperature & pressure liquid. Before moving and disassembling the pump, it must be drained or the shut-off valves on both sides must be closed to avoid burns;

2. In winter, If

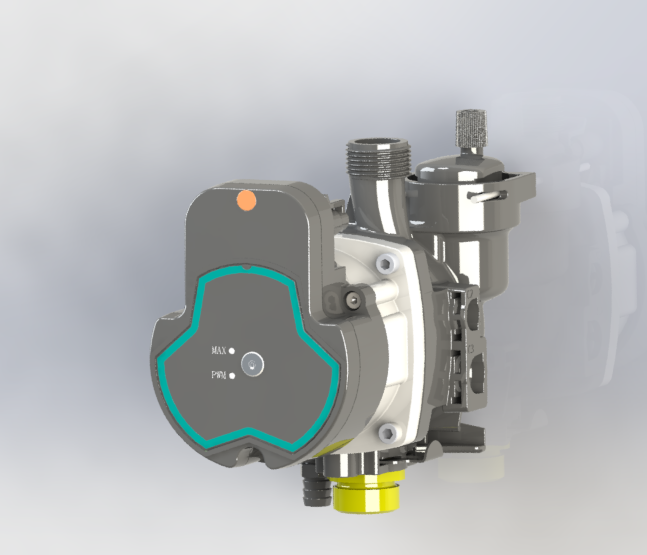

GPA15-7.5 III U Z108

APPLICATION FIELD

1. Apply to wall hung gas boiler system.

2. Transfer the electrical energy to hydraulic pressure.

3. Transfer the heating water.

4. Exhaust the air from HW system.

5. Suitable for wall hung gas boiler: 18kW, 24kW, 28kW, 31kW, etc..

FEATURES AND BENEFITS

1. Shinhoo wall hung gas boiler pump is composed of stator, rotor, shield cover, vent valve and so on.

2. Sealing: stator and rotor sealed up with stainless steel shield cover, integral structure sealed up with

3. heat-resisting rubber washer, rather than mechanical seal. This ensures no leakage.

4. Lubrication and cooling: use internal circulation, lubricated and cooled by circulated liquid.

5. Motor: Insulation Class is H. Internal thermal protector. Single speed and three speeds are available.

6. Protection Class: IP 42.

7. Venting: based on floating ball principle, an integrated air venting system can exhaust the air out of water

8. Automatically during liquid injecting and running.

9. Noise:The noise of pump that works in a boiler with rated flow is less than 42 dB(A).

DESCRIPTION

Operation Condition

Power: AC230V, 50Hz

The minimum start-up and operation voltage: 175V.

Different voltage and frequency is available according to customer’s requirement . All performance curves in this catalogue are based on pumps with power supply of AC 230V, 50Hz.

The max. system pressure: 3 bar.

In order to avoid cavitation damage to the pump bearing, the minimum inlet pressure should be kept as below: 1bar.

Ambient temperature must be lower than liquid temperature, in order to aviod condensate water produced in the interior of stator.

Transmission fluid: Thin, clean, non-corrosive and non-explosive liquids, without any particle, fiber or mineral oil. Pump can not be used for transferring flammable liquids such as diesel, petrol and so on.

Dry running: Pump is lubricated by water, dry running must be no more than 10s.

Installation:

The axial direction of pump must be parallel to ground and the vent valve should be installed vertically.

The user should not tighten the nut of valve.

It should be correctly installed by professional person

MASTER H 25-9-130 PRO

Master H 25-9 Pro Heat Pump Circulator Pump

TECHNICAL DATA

Power supply voltage:220~240V,AC,Protective earth

Motor protection:No external protection required

IP class:IP44

Insulation class:H

Humidity(RH) :Max 95%

System pressure:1.0 Mpa

Compliance:EMC/RoHS/REACH/TUV/CE/EEI

Environment temperature:-30℃~55℃

Temperature class:TF 95

Liquid temperature:2~+95℃

Connection/Unions:Shinhoo Standard/ Molex/TE

APPLICATION FIELD

1. Domestic heating and water supply system

2. Air and ground source heat pump system

3.Air-conditioning system

4. Industrial hot water circulation system

5.Solar thermal system

6. Compatibility with R290 All Inverter Heat Pump

FEATURES AND BENEFITS

Scope of use

Air source heat pump combined supply system

Product certification

The product meets the requirements of TUV、CE、EMC、RoHS、REACH、EEI≤0.23-part3 certification

Advantage

Easy installation and operation

Equipped with Self Adapting mode AUTO (default setting), pump runs once the power is connected and adapts its performance according to actual system needs.

Control is effected by digital pulse-width modulation (PWM) low-voltage signal, enabling the pump to be used to meet different flow requirement in various systems.

Low noise and high comfort

Noise index: ≤42dB(A)

Low energy consumption

Lowest power consumption up to 6W

Multiple protection

With over-voltage and over-current protection

Eco-Design Benchmark

EEI≤0.21-Part 3

Quick release power plug

Start-up and stop the pump quickly.

DESCRIPTION

Basic parameters

Maximum flow:4.5m³/h

Maximum head:9m

Rated flow:2.5m³/h

Rated head:6.5m

Rated voltage:220-240V AC

Rated current:0.9A

Frequency:50/60Hz

Input power:95W

Design pressure:1.0MPa

Noise:<36dB(A)

Standby power:≤3W

Degree of protection:IP44

Surge current:<5A

Temperature class:TF95

Weight of bare pump with wire:2kg±5%

Speed:1550~4400rpm

Media requirements

Medium: water or water + glycol (≤ 50%)mixture

Medium temperature : 2℃∼95℃

PH value of medium :6.5-8.5

Medium hardness :25°dH

Content of

MASTER SD 25-7.5-180

Master SD 25-7.5 High Efficiency Circulator Pump

TECHNICAL DATA

Model:Master SD 25-7.5 130/ Master SD 25-7.5 180

Maximum flow (m³/h):3.8

Maximum head (m):7.5

EEI:EEI≤0.20-Part2

Rated voltage :220-240V AC

Rated current:0.5 A

Frequency:50/60Hz

Maximum power:60 W

Design pressure:1.0MPa

Noise:≤42dB(A)

IP class:IP44

Insulation class :H

APPLICATION FIELD

1. Domestic heating and water supply system

2. Air and ground source heat pump system

3. Air-conditioning system

4. Industrial hot water system

5. Solar thermal system

FEATURES AND BENEFITS

1. Intuitive one-button operation makes selection of any control mode simple

2. No external motor protection required reducing installation time

3. High-torque start improves startup under harsh conditions

4. Maintenance free and noiseless due to canned-rotor design and use of robust components

5. Fast connection plug makes electrical installation quick, safe and easy

6. Insulating shells are available to minimize heat loss in heating systems

7. The pump features three constant-curve modes, proportional pressure curves, constant pressure curves, auto and night mode.

8. In terms of electricity consumption, the unique operation mode makes high efficiency circulator pumps more energy saving.

9. High efficiency circulator which features well-designed compact structure, integrated controller and frequency converter.

10.It is easy for installation and operation in most fields of applications.

DESCRIPTION

Media requirements

Medium: water or water + glycol (≤ 50%) mixture

Medium temperature : 2℃~110℃

PH value of medium :6.5-8.5

Medium hardness :25°dH

Content of solid impurities in medium: diameter and length direction of solid impurities ≤ 0.1mm, and volume ratio≤ 0.1%.

Service environment requirements

Usage: keep the shaft horizontal

Altitude: < 1000m

Operating ambient temperature: 0 ℃ ∼ 70 ℃

(there is no freezing in the pipeline and water pump)

Operating ambient humidity≤95%

Storage environment requirements

Storage ambient temperature: - 30 ℃ ∼ 70 ℃

(there is no freezing in the pipeline and water pump)

Humidity of storage environment: ≤95%

Start and stop of pump

Starting time: the starting time of the water pump is less than 3S, that is, the time from power on to reaching the maximum speed

Shutdown time: the shutdown time of the water pump is less than 1s,that is, the time from power failure to shutdown of the water pump