MARELEC Food Technologies NV

MARELEC Food Technologies NV

Redanweg 15

8620 Nieuwpoort

Belgium

Telephone+32 58 22 21 11

Fax+32 58 23 92 80

About us

INNOVATIVE FOOD PROCESSING SOLUTIONS

MARELEC Food Technologies designs and manufactures high-technological portioning and grading systems for food processing companies in the fish, poultry and meat industries. MARELEC is a world market leader with the PORTIO, an intelligent portion cutter that cuts fresh meat, poultry or fish into fixed weight portions.

MARELEC, based in Belgium, focuses on export and has a worldwide network of more than 50 exclusive distributors. These are supported by a strong team of technical and commercial sales engineers, resulting in an export of more than 95%.

The machines are designed and developed by a young team of enthusiastic engineers, each of whom is a specialist in the field of mechanical design, electro mechanics and electronics. In addition, all software is written in-house. This for the operating systems of the machines as well as for the own production management software MATRIX.

After design and development, all machines are produced, assembled and tested at the workplace in Nieuwpoort by a team of welders, mechanics, electricians and engineers.

In the meantime, thousands of systems are operational and an efficient team of enthusiastic service engineers guarantees optimal technical support worldwide, and this on a 24/7 basis.

Adding value by portioning to fixed weights

MARELEC Food Technologies has become a market leader with its PORTIO range. These portion cutters cut fresh meat or fish into portions of fixed weight of fixed thickness. The machines use the proven technology of laser guided cameras to scan the volume. Knowing the density, the intelligence calculates instantly where to cut to make the portion with the programmed weight.

Production efficiency is guaranteed as the software always calculates to go to zero waste or maximum yield.

The MARELEC range has grown tremendously over the last years to accommodate all possible applications. We have Portion Cutters available that cut under an angle as well as dual lanes for high capacity portioning and a variety of wide belts to portion large products. The most recent developed machine, the PORTIO B, is able to portion pork loins with bones.

All MARELEC PORTIOs are designed for optimum cleaning and hygiene. The machines can be opened completely for easy access. Operating is easy to allow fast fine tuning of the programs. Options exist to calculate the density and to hold the products in place when cutting.

The PORTIO can be placed in line with a grader, to maximize the yields. In this case, the machine selects the optimal cutting pattern to reduce trim.

Fast, accurate and highly advanced grading solutions

Next to the PORTIO, MARELEC is also specialised in custom made designing and manufacturing of weighing and grading solutions for the poultry, meat and fish industry.

Grading is weighing products individually and sorting them to the right weight range. Our grading solutions are not limited to sorting, but can also be equipped with intelligent batching algorithms. A batch is a combination of products that have a certain required weight. The grading system will use intelligence to reach as close as possible to these batch -weights. E.g. a customer wants to create fixed weight trays of 1kg. The machine will try to finish each batch as close as possible to 1 kg, resulting in the lowest give-away possible.

Keywords

- Slicer

- Grading

- Portioning

- Portion Cutter

- MARELEC

Our Products

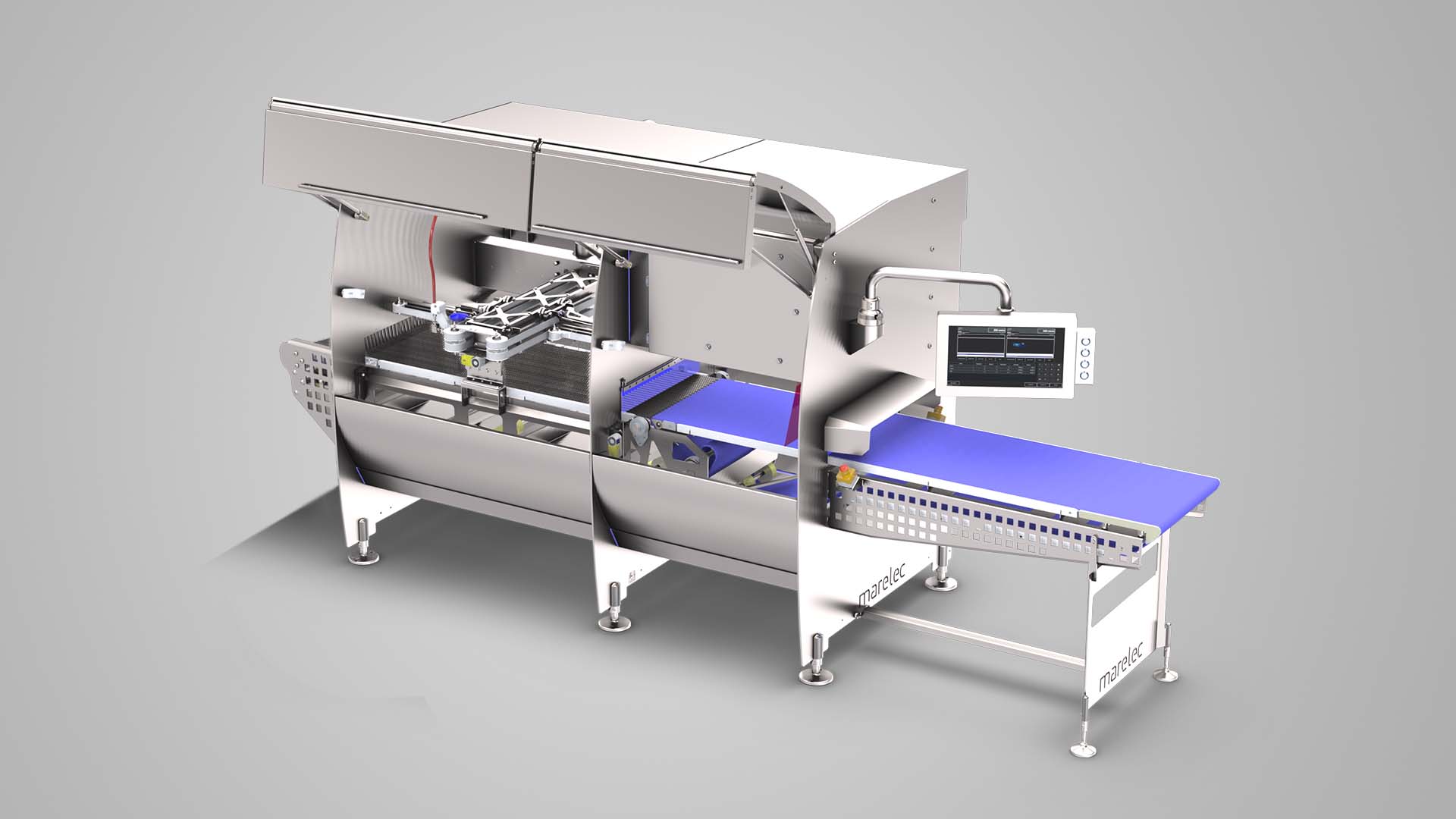

Intelligent Waterjet Cutter PORTIO JET

MAXIMIZING YIELDS WHEN CUTTING POULTRY FILLETS OR DEBONED LEG MEAT INTO PREDETERMINED SHAPES OF FIXED WEIGHT WITH THE MARELEC PORTIO JET.

The MARELEC PORTIO JET is a state of the art waterjet cutter based on more than 15 years successful experience in portioning. The waterjet cutter is designed to portion boneless poultry products such as chicken breast and boneless leg meat into predetermined customized shapes while maintaining fixed weights.

The PORTIO JET has been developed to maximize yields when cutting poultry fillets or deboned leg meat into predetermined shapes of fixed weight. The camera/laser combination scans to the highest accuracy, before the intelligent cutting algorithm calculates the optimal cutting pattern.

There is a list of predetermined cutting patterns programmed, from which parameters such as weight and size of the portions can be adapted. There is also a mode where the cutting pattern can be drawn on a scanned product to define specs.

Over 300 programs can be stored with a customized name, making it possible to switch cutting patterns within seconds. Multiple streams of products can be loaded next to each other on the 600mm/24” wide belt and work with multiple applications simultaneously.

Typical applications include cutting chicken fillets into fixed-weight portions, cubes or strips. Boneless leg meat can be trimmed down and portioned into fixed-weight portions, better known as steaks or thigh patty. Very popular patterns are strips or cubes, such as karaage, kakugiri or BLK.

The PORTIO JET is built in a modular way. It starts with the base module, in which all electronics, scanning and HMI are integrated. As standard, this base unit controls a module with two cutting stations. This combination is called PORTIO JET 2.

The standard unit can be extended into a series of modules, each with two high-pressure waterjet nozzles - up to four modules or eight stations in total. Thanks to the modular design, these extra stations can be added whenever your volumes require it.

The MATRIX J software collects all production data from the PORTIO JET, enabling it to generate production reports per shift or program and to trace changes at a machine level. MATRIX J software enables users to remotely create programs offline and monitor the machine status through an event log.

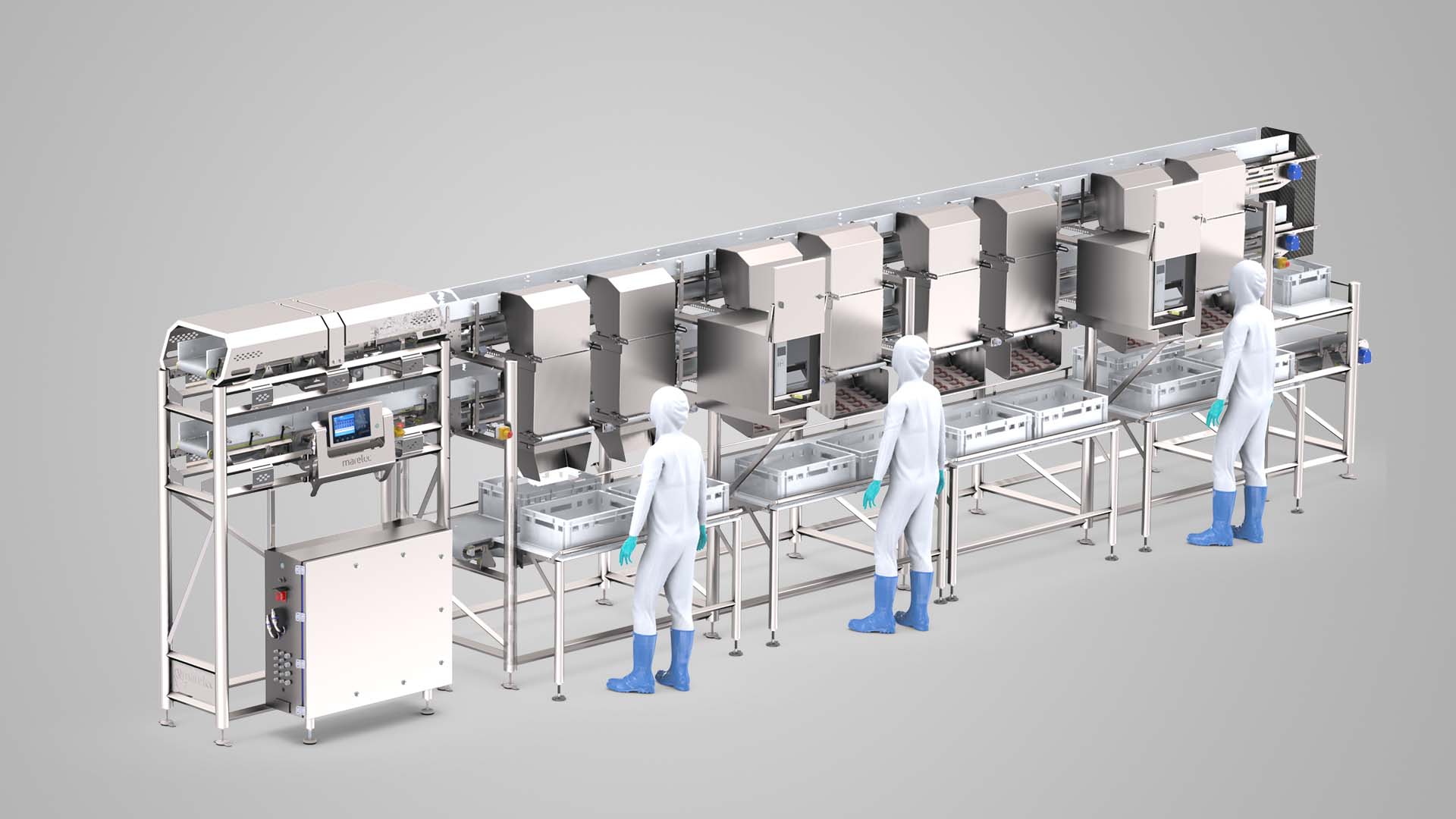

Intelligent Grading Solutions

INTELLIGENT GRADING SOLUTIONS WITH HIGH CAPACITY TO OPTIMIZE PRODUCTION AND YIELDS WITH AN ABSOLUTE MINIMUM OF GIVEAWAY.

Value is added by cutting up the chicken into parts. The volumes of processed chicken in today’s slaughterhouses require high-performance, intelligent Grading Solutions. MARELEC has designed a wide range of options on infeed systems, weighing and sorting methods for all different kind of cutups that will meet the high demands of actual production requirements.

To ensure the maximum output from the smallest possible footprint, MARELEC designs dual-lane graders. Common batching bins bring the parts within the same weight range from both the upper and the lower lane into presentation trays or directly into boxes.

Printers can be installed in-between the stations to print labels with the production data. An exit conveyor delivers the boxes towards the end of the line.

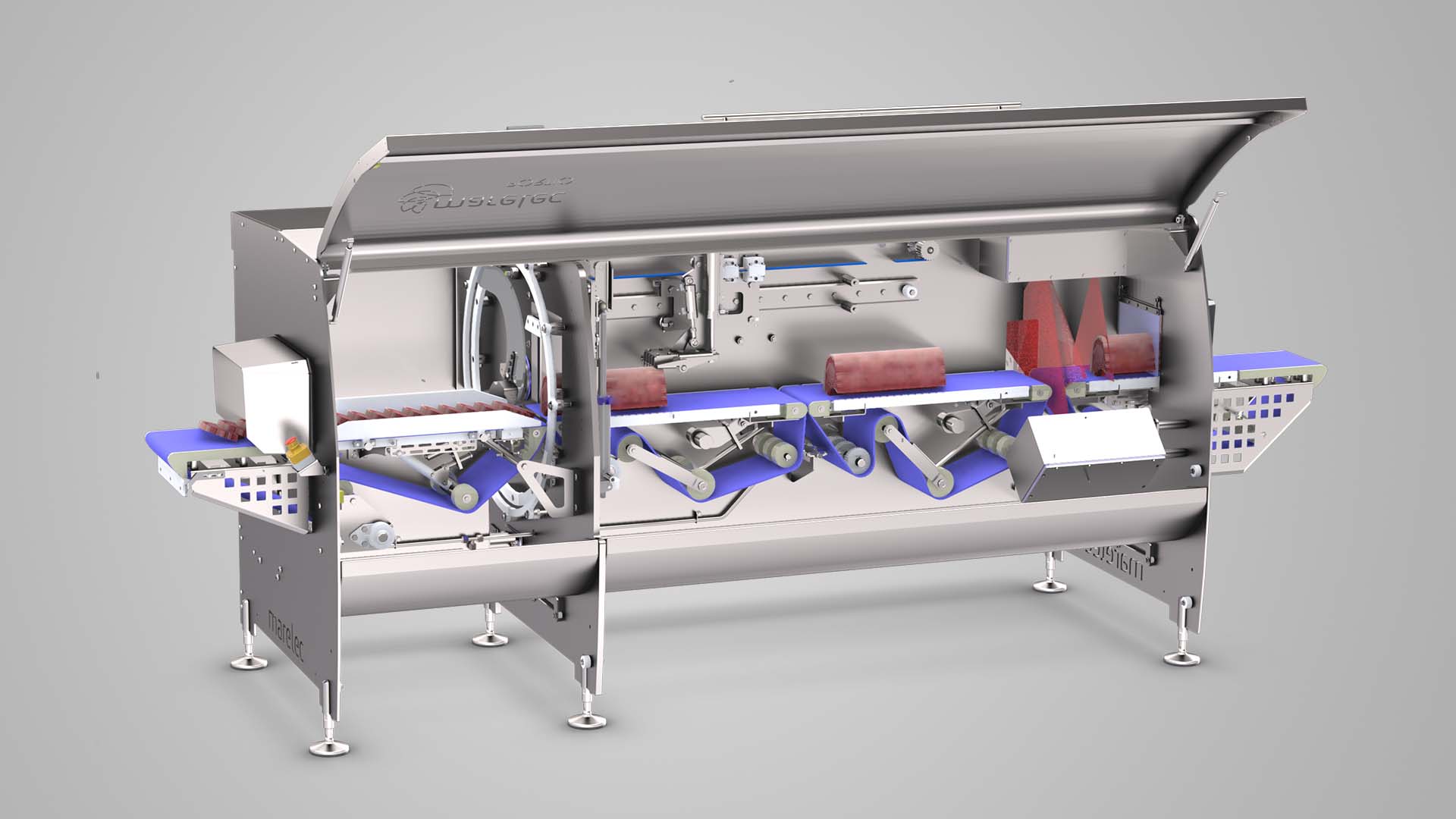

Intelligent Heavy-Duty Portio Cutter PORTIO B

The technology in the PORTIO B has gone to a next level to be able to cut pork chops. Because of the irregular shape, scanning over 360° is a must. 3 cameras, with a 120° spacing in between, scan all around the meat, to determine the exact shape and volume. Knowing the shape in combination with the density allows the intelligent software to calculate instantly where to cut to have a portion of the target weight.

To prevent the product from moving during the cutting, several product holders act simultaneously, while the product is kept in place on a belt with specially designed spikes. A gripper with pneumatically controlled fingers holds the loins in place during cutting, in combination with a holder from the top and from the side. The specially designed knife has 2 sections: the sharp knife section to keep the quality of the meat and a serrated section to cut the bone easily.

Cube Cutting Line

SEPARATING STRIPS TO REDUCE LABOR WITH THE MARELEC STRIP SEPARATOR (STS)

Cutting cubes from chicken fillets adds a lot of value to your products. The cubes are the basis for various meals all around the world. It is essential to control the weight and shape of the cubes when producing fixed-weight packs for retail or food service. In order to be profitable, cubes must be cut at high volumes with minimum labor and maximum efficiency.

The development of the strip separator was the right step for MARELEC due to the increasing worldwide demand for cutting cubes. Cutting cubes with a MARELEC cube cutting line first involves a portion cutter that cuts strips from a fillet.

The strips are then singluated and alligned by the Strip Separator. Operators check for default and perform a quality check.

In third stage, the second portion cutter cuts fixed-weight cubes. The strip separator enhances the efficiency of the entire line. It reduces labor reduction and increases of throughput. Furthermore, it increases yield with a better-looking end-product because the strips are almost perfectly aligned. This alone makes it a worthy investment.

The first dual-lane PORTIO 1DAP will scan and cut the fillets into strips on both lanes. The intelligence of the first portion cutter ensures that the front and back trims are kept to a minimum. Depending on the size and shape of the raw material, the portion cutter will calculate where to make cuts to create the best-looking strips. Flattening the chicken fillets prior to cutting the strips will help to create a better looking strip. One benefit is that it increases the efficiency of the strip separator which means less work for the operators.

The second PORTIO 1DAP is placed at 90° so the individual strips have the right orientation and cuts the strips into fixed-weight cubes. This portion cutter also uses its intelligence to cut at the highest yield possible.

With a constant and efficient infeed of the fillets, you will be surprised by how many ton per hour you can produce.

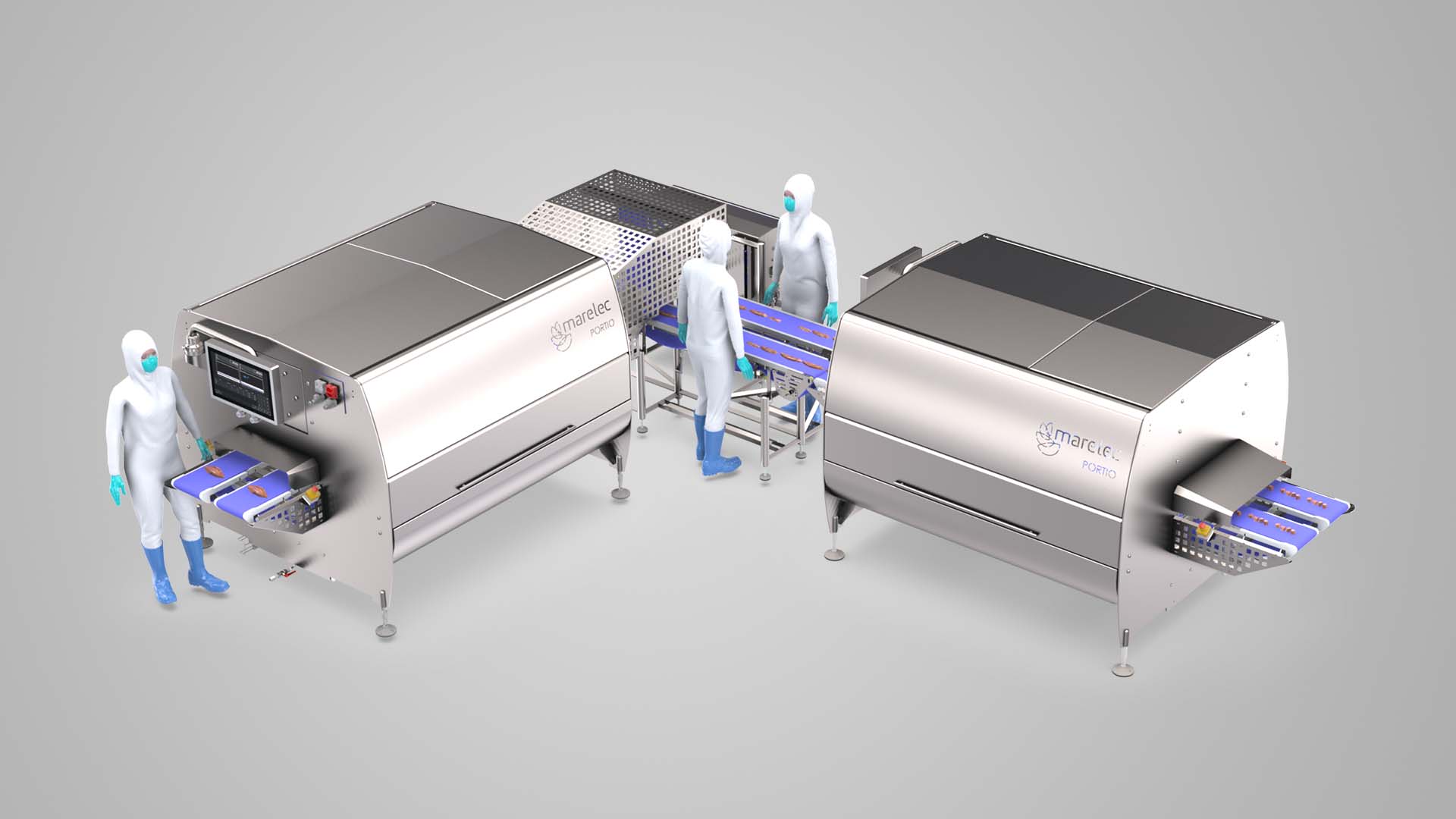

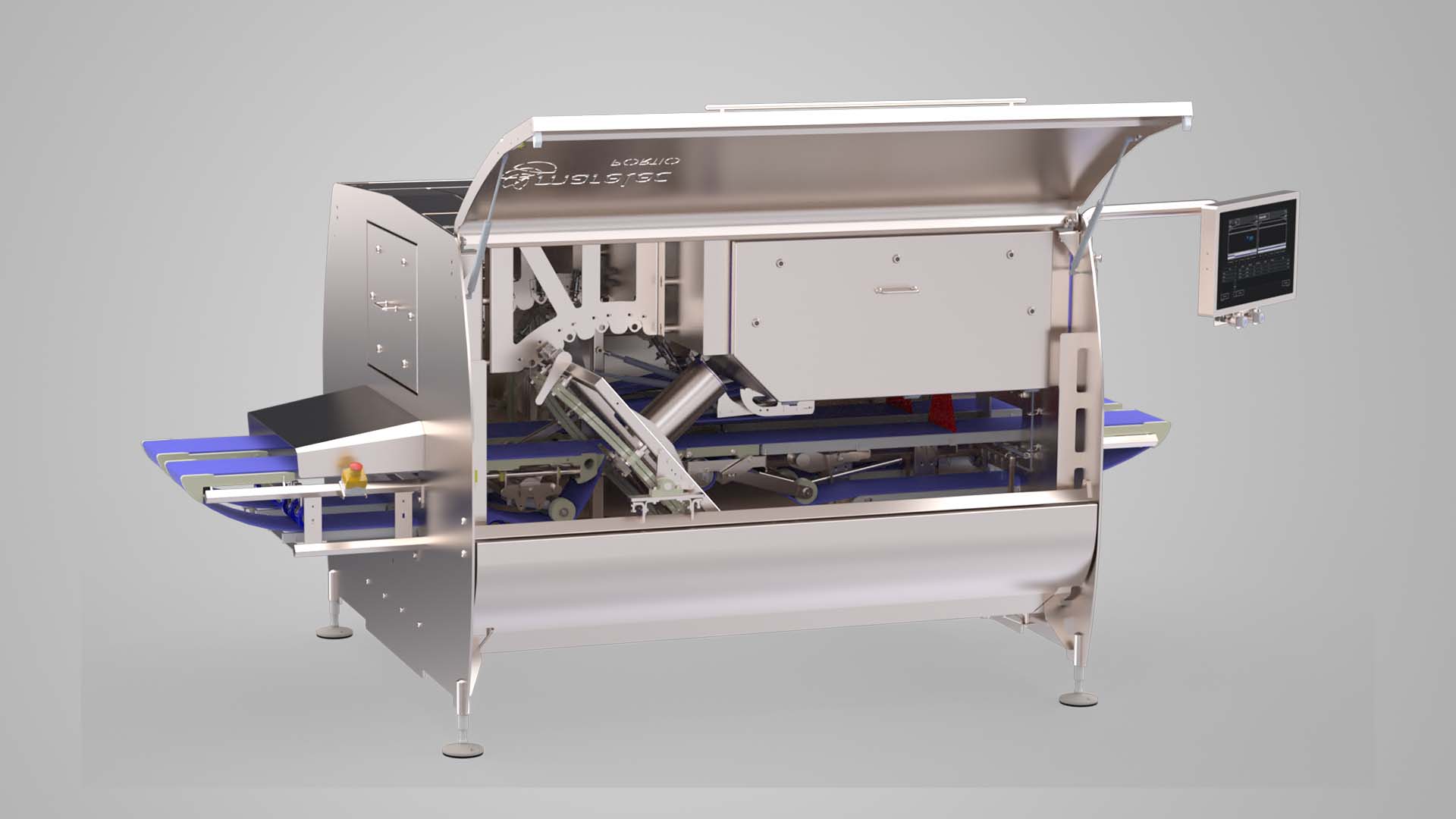

Intelligent Portion Cutter

MARELEC Food Technologies has become a market leader with its PORTIO range. These portion cutters cut fresh meat or poultry into portions of fixed weight of fixed thickness. The machines use the proven technology of laser guided cameras to scan the volume. Knowing the density, the intelligence calculates instantly where to cut to make the portion with the programmed weight.

Production efficiency is guaranteed as the software always calculates to go to zero waste or maximum yield.

The MARELEC range has grown tremendously over the last years to accommodate all possible applications. We have Portion Cutters available that cut under an angle as well as dual lanes for high capacity portioning and a variety of wide belts to portion large meat products.

All MARELEC PORTIOs are designed for optimum cleaning and hygiene. The machines can be opened completely for easy access. Operating is easy to allow fast fine tuning of the programs. Options exist to calculate the density and to hold the products in place when cutting.

The PORTIO can be placed in line with a grader, to maximize the yields. In this case, the machine selects the optimal cutting pattern to reduce trim.